The vulnerability of production and supply networks has come into particular focus in recent years, first with the pandemic and then with the war in Ukraine. Industrial companies in particular have experienced how costly the lack of resilience in their value creation processes can be. Even ignoring unforeseeable events, it is clear that in the future the pressure on production and supply chains will continue to increase – this is ensured, for example, by the increasing scarcity of raw materials and the ever greater volatility of the markets. Against this background, strategic planning of the Production Footprint is becoming a central task for companies. Whereas the focus used to be on individual sites, we now look at the network as a whole. ConMoto has developed a structured approach for the integrated optimization of production networks. Based on the strategic goals of a company, a Production Footprint is designed for the company and implemented, with which economically successful value creation is possible even under difficult conditions.

Defining strategic goals: an often neglected task

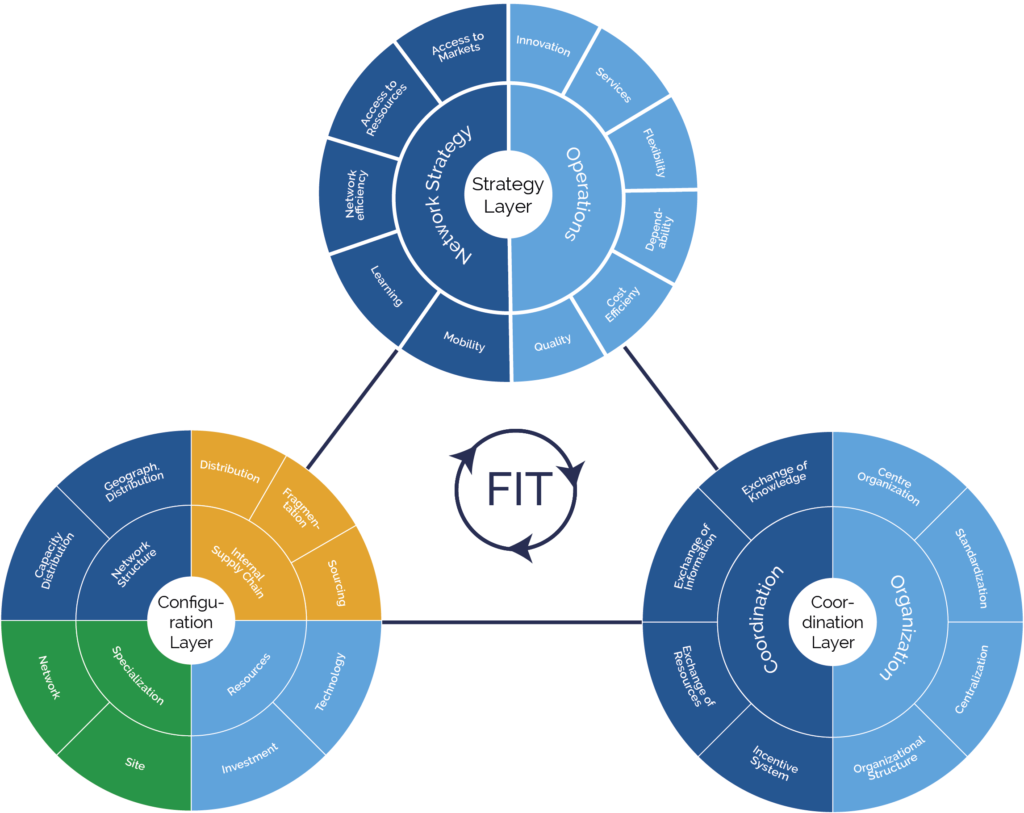

The process of redesigning the Production Footprint begins with defining the strategic path of the company. This sounds like a given, but it is an important and complex task that is often neglected. The honest answer to the question of what a company’s strategic focus is has a major impact on the design of production and supply networks. Is innovation a core issue or is it cost leadership? Is production flexibility a success factor or is secure access to resources more crucial? How can differentiation from the competition be achieved? ConMoto considers and prioritizes these and other strategic aspects when setting goals with its customers.

Also part of defining strategy is the quantification of goals as Key Performance Indicators (KPIs). During implementation, the KPIs can then be used to track the effectiveness of the concepts and activities. The indicators will be added step by step as the project progresses, if necessary.

Through clean analysis to a detailed target scenario

Against the backdrop of this strategic map, the current Production Footprint is analyzed from different angles to identify a profile of strengths and weaknesses. This transparency is in turn the starting point for the development of target scenarios for the further development of the production and logistics network in a three-stage process. Together with the customer, ConMoto clarifies in increasing detail, for example, the technology concept, the depth of value creation (make-or-buy), the sourcing strategy (global vs. local) and location issues. By working with alternative scenarios in close coordination with management and other stakeholders, a profile of requirements for the redesign of the production network is created, which enables informed decisions for portfolio development, investments or relationships with suppliers in the supply network. Various scenarios are evaluated technologically and calculated economically. ConMoto supports with analysis tools and an extensive benchmark database on topics such as factor costs and technology. At the end of this process, a decision is made for a concrete target scenario.

No success without stringent, effective implementation

Redesigning a Production Footprint requires a variety of implementation measures in all areas of a company. Successful implementation depends on a powerful project organization that plans and initiates change and makes progress transparent. ConMoto has more than 30 years of know-how in implementation management. We provide our customers with the methodological knowledge and implementation tools they need to track the progress of the various sub-projects and drive them forward in a targeted manner. This includes continuous communication with stakeholders in the change process as well as monitoring budget adherence and schedule. The economic success of a production network that meets the strategic requirements of a company lies in the implementation of the numerous changes: at the production sites and suppliers as well as in product development or in the sales organization of a company. The performance improvements of an optimized Production Footprint can be demonstrated in detail using the KPIs already defined in the target setting. Our customers attest ConMoto a pragmatic, fast and precise approach – from strategy finding to target definition to implementation. We will gladly provide you with references. Contact us at business@conmoto.de.

Deutsch

Deutsch