Success factor process optimization

Process optimization in all phases of production is an important lever for increasing the productivity of your company. ConMoto supports you with targeted optimization projects for higher quality at lower costs. In doing so, we rely on lean principles, methods such as value stream mapping, kaizen and kanban, as well as on score tests and other analysis methods we have developed ourselves.

A key focus of process optimization is the judicious use of automation technologies through the introduction of robots, CNC machines and automated conveyor belts. This increases the efficiency of their production and reduces the workload for employees. Automation also enables greater accuracy and consistency in production, resulting in improved quality and reduced scrap rates.

New technologies also play an important role in data analysis and process controlling. We continuously identify potential for improvement and uncover sources of error. This enables your business to prevent problems before they arise.

Talk to us.

Every positive business relationship begins with a good conversation. Leave your email address. We are looking forward to get in touch.

It’s results that count: securing sustainable change

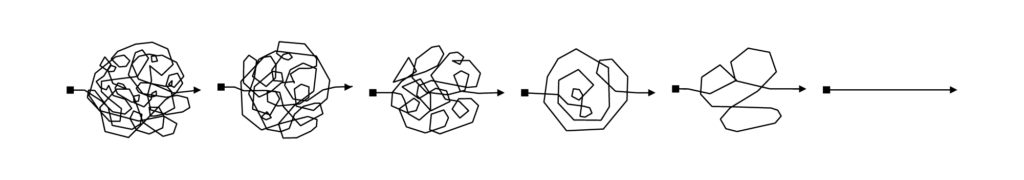

ConMoto sees its most important task in designing process optimization and change to establish a self-reinforcing system, which can be flexibly adapted to new circumstances. This is the only way to achieve effective and sustainable improvements. Particularly in optimization projects, the rule is: it’s results that count. Project successes show up as a positive impact on EBIT – otherwise they are not successes.

Deutsch

Deutsch